Tech uploads a video or photo of the issue from the job site.

A second set of eyes on every service call.

Upload one site photo or short clip. Wingman returns the next safe diagnostic steps in checklist form, with clear if/then branches.

Wingman identifies likely cause and safety checks.

Tech follows one step at a time and confirms results.

Live-style demos: what tech sends, what Wingman returns

Case 1 image + Case 2 hosted video.

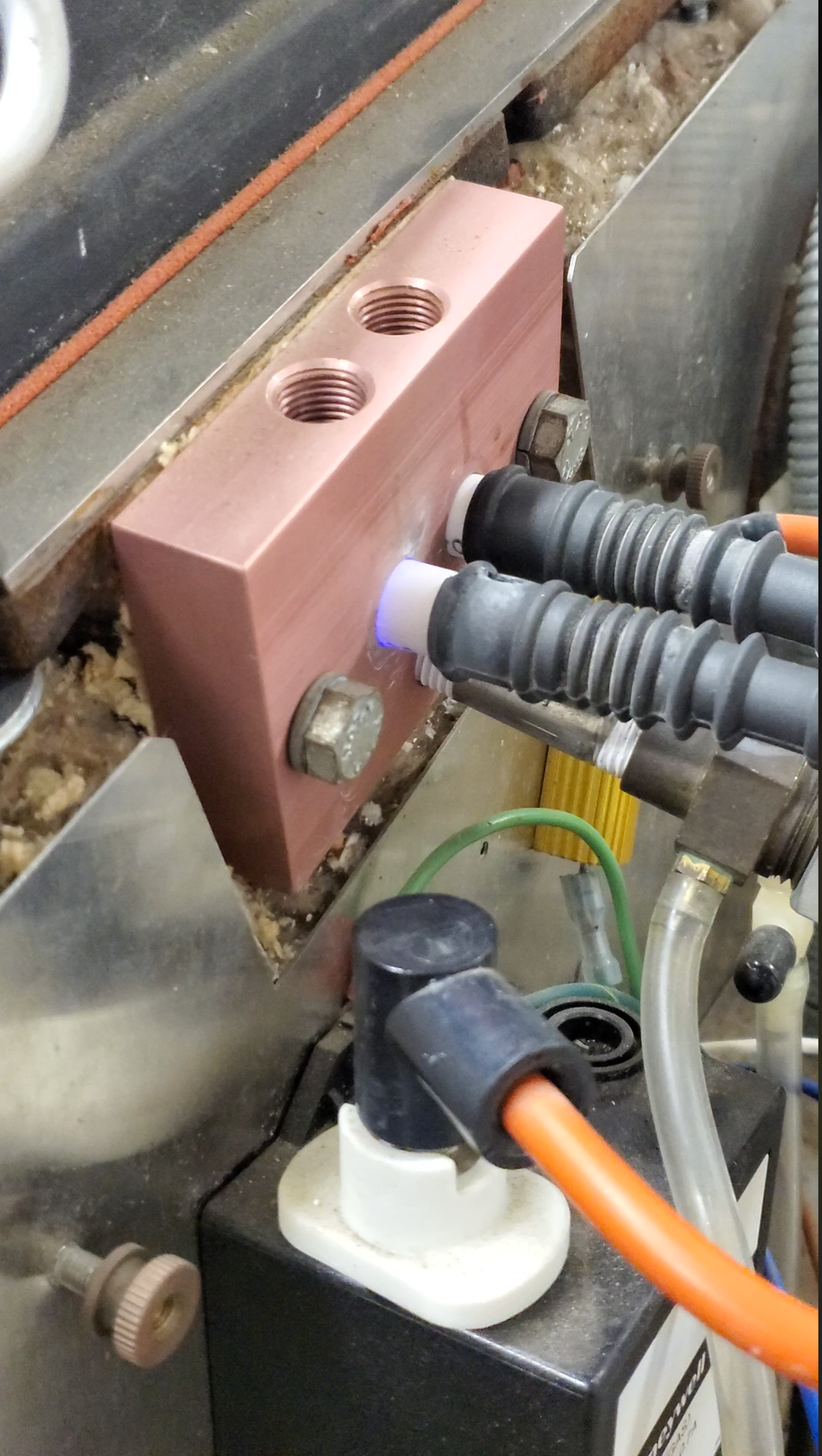

Case 2: Boiler flame rod arcing

Input image -> structured safety + next-step output

Input

https://wingman-bucket.sfo3.cdn.digitaloceanspaces.com/demo-flame-rod.png

refresh this page

Wingman output

What I see

Arcing appears at the left ceramic insulator base, suggesting high voltage is tracking to ground instead of the intended ignition path.

Safety first

Stop firing the unit. Power down and close manual gas valve before touching components.

Next steps

- 1Inspect ceramic for cracksHairline cracks can cause immediate tracking.

- 2Clean mounting areaRemove soot, moisture, or conductive residue.

- 3Check boot and connectorLoose or split boot can arc to the burner block.

Stop condition

If arcing persists after rod and boot checks, escalate for ignition component troubleshooting.

Case 1: AC short cycling

Input video -> loss-of-charge diagnosis flow

Input

Final case footage with ending and resolution context.

Wingman output

What I see

Trane outdoor unit with spine-fin coil, probes connected, and visibly dirty coil. Pressure behavior indicates low-pressure protection trip after startup.

Safety first

Panel is open with live high-voltage components. Keep clear of contactor and capacitor terminals, fan blade, and avoid refrigerant venting while handling probes.

Diagnosis + next steps

- 1Confirm diagnosisLow suction + low head + near-zero subcooling indicates severe loss of charge, not restriction.

- 2Leak search outdoor firstInspect spine-fin rub points and accumulator underside for oil marks/shiners.

- 3Then inspect indoor evaporatorIf outdoor is clear, move to evap coil as common leak source.

- 4Pressure test properlyRecover charge and perform standing nitrogen pressure test (300+ PSI) to locate leak.

Watch for

Standing pressure only means some refrigerant is present, not that charge is correct. Do not top off before locating and repairing the leak source.

Run this on real calls with your team. We are onboarding a small pilot cohort now.

Book a 15-min demoWingman provides decision support and checklist guidance. Always verify against manufacturer documentation, code, and licensed judgment.